About Us

Taizhou Eastern CNC Technology Co., Ltd.

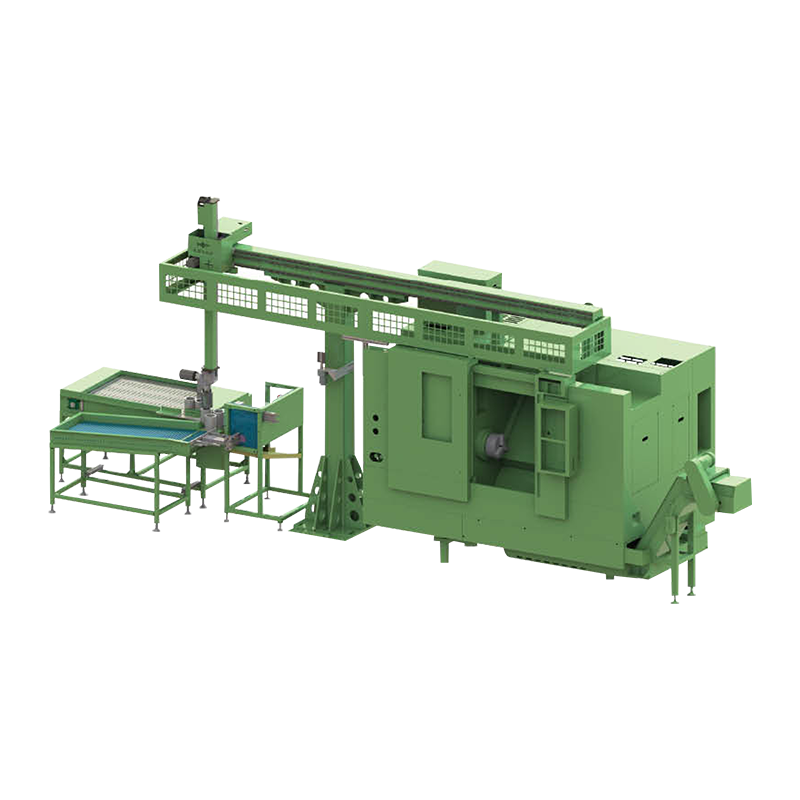

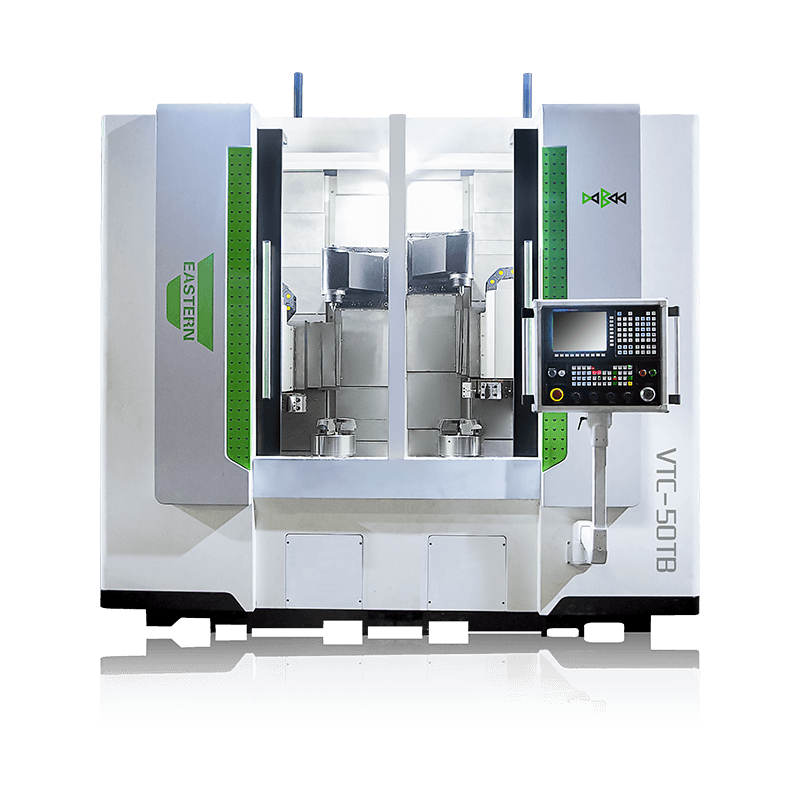

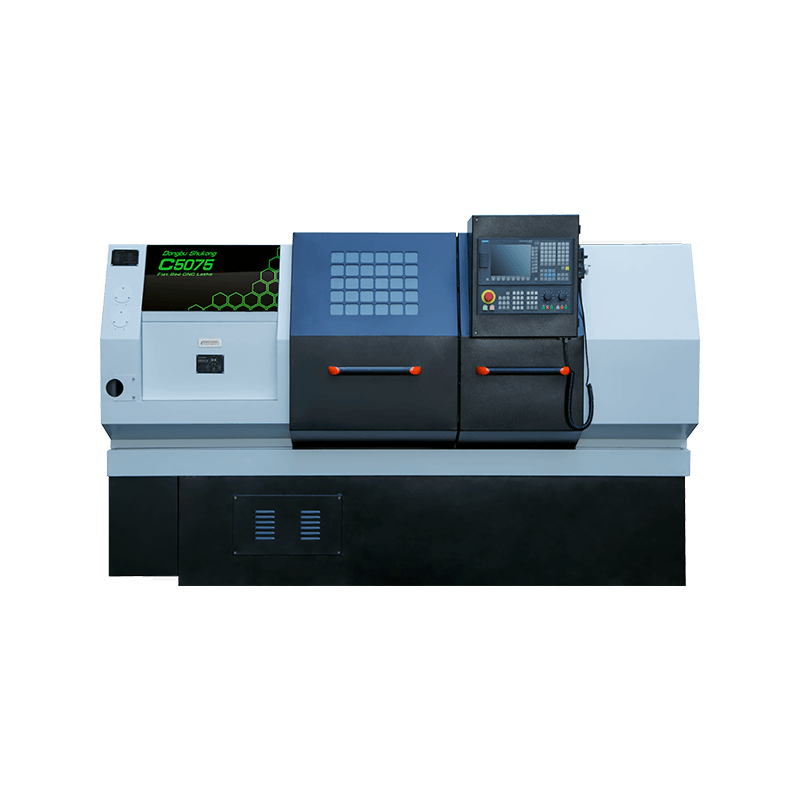

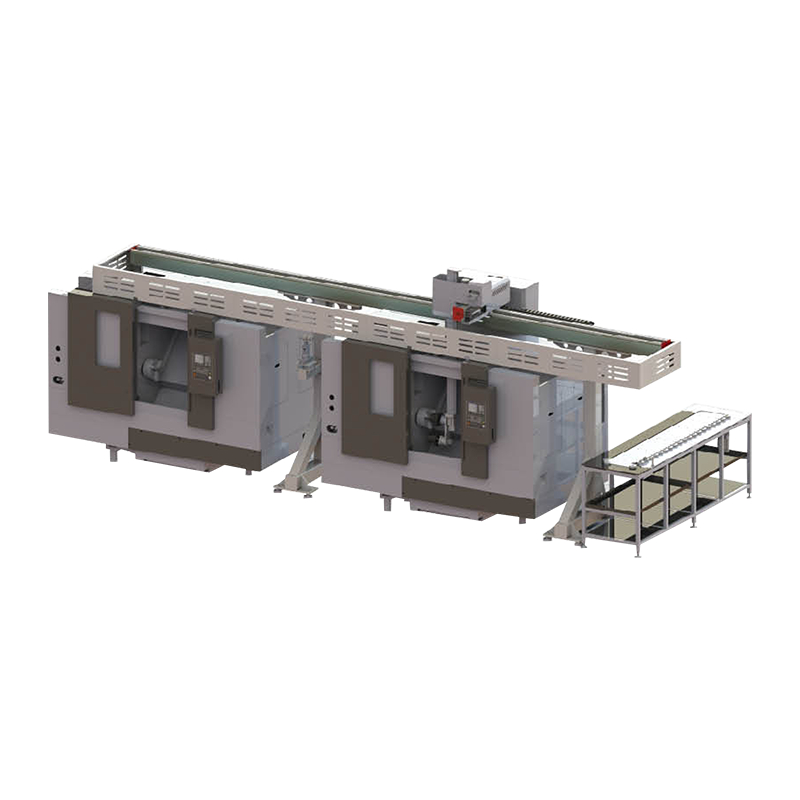

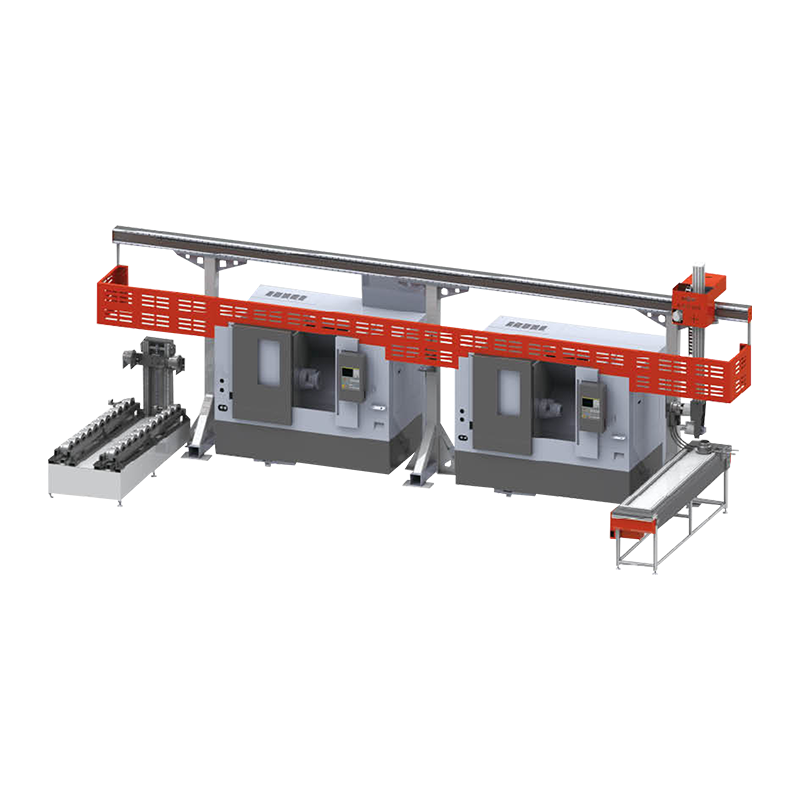

We are a well-known brand and professional wholesale 160160 Heavy Duty G Series CNC Lathe Automation Production Line of 160160 Heavy Duty G Series CNC Lathe Automation Production Line in China. It is committed to providing professional machine tools and production application solutions to global users, and actively provides customization. It has more than 650 employees. With different models and more than 40 derivative products, we strive to achieve the vision goal of "building a famous brand in the machine tool equipment manufacturing industry".

Certificate Of Honor

News

How to buy CNC machine tools

-

01

Contact Us

All of your quotes will be answered within 2 hours by our professional sales support.

-

02

Get A Free Quote

Use reliable parts and components to ensure product quality.

-

03

Fast Delivery

You can expect your order fulfilled within 60 days after placing the order.

-

04

After-sale Support

You can enjoy a one-year many for all of our produons.