OEM T55 / T55L / T55M CNC Slant Bed Lathe With High Accuracy Supplier

T55 / T55L / T55M CNC Slant Bed Lathe With High Accuracy

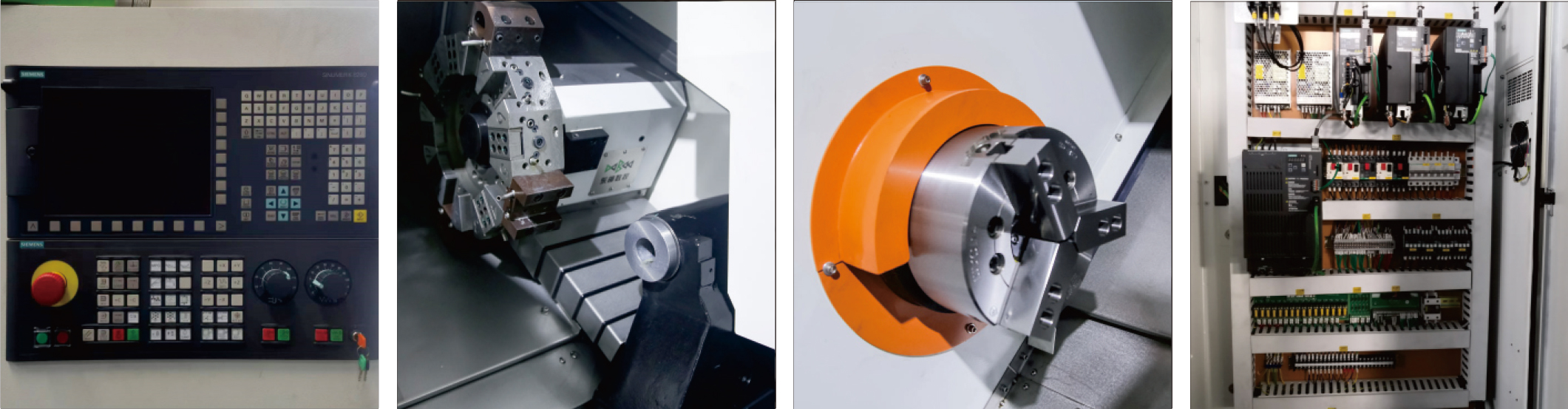

T55/T55L/T55M CNC Slant Bed Lathe With High Accuracy can automatically complete the cutting of internal and external cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering and other processes for various shaft and disk parts, and can Turning of metric straight threads, end face threads, inch straight threads and tapered threads, etc. It adopts a high-rigidity hydraulic servo turret, optimizes compensation through the servo system, and cooperates with the servo spindle to achieve multi-axis linkage. It can complete functions such as spindle positioning, rigid tapping, and curved surface milling, which greatly enriches the functions of the machine tool and improves the machine tool's performance. Adaptable to meet the processing needs of various types of parts.

|

|

Maximum Machining Diameter: 300mm |

|

|

Maximum Machining Length: 370mm |

|

|

Chuck Size: 8" inch |

-

DETAIL PARAMETERS

-

VIDEO DISPLAY

Feature:

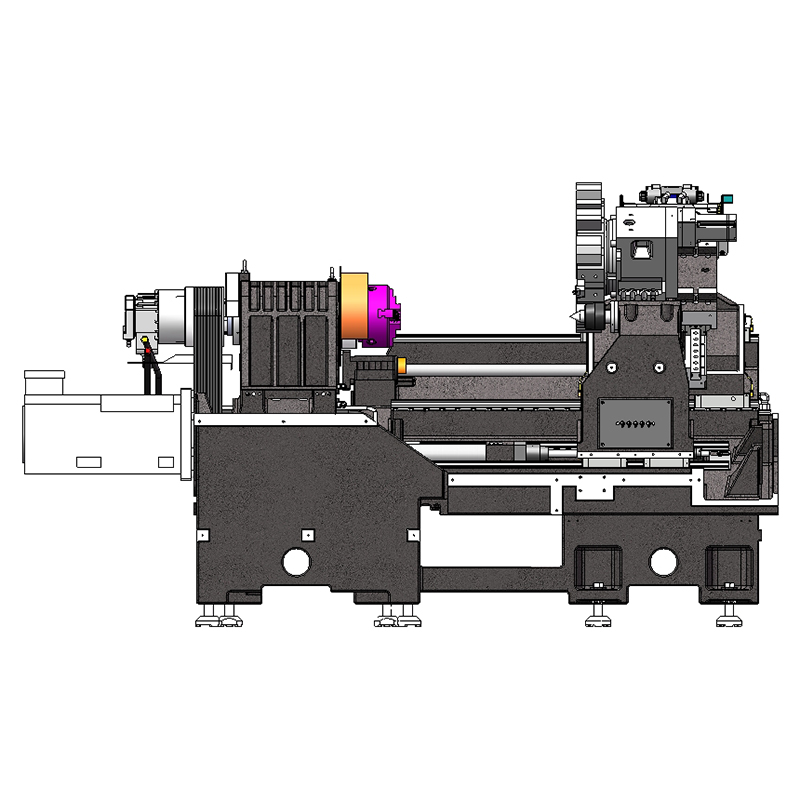

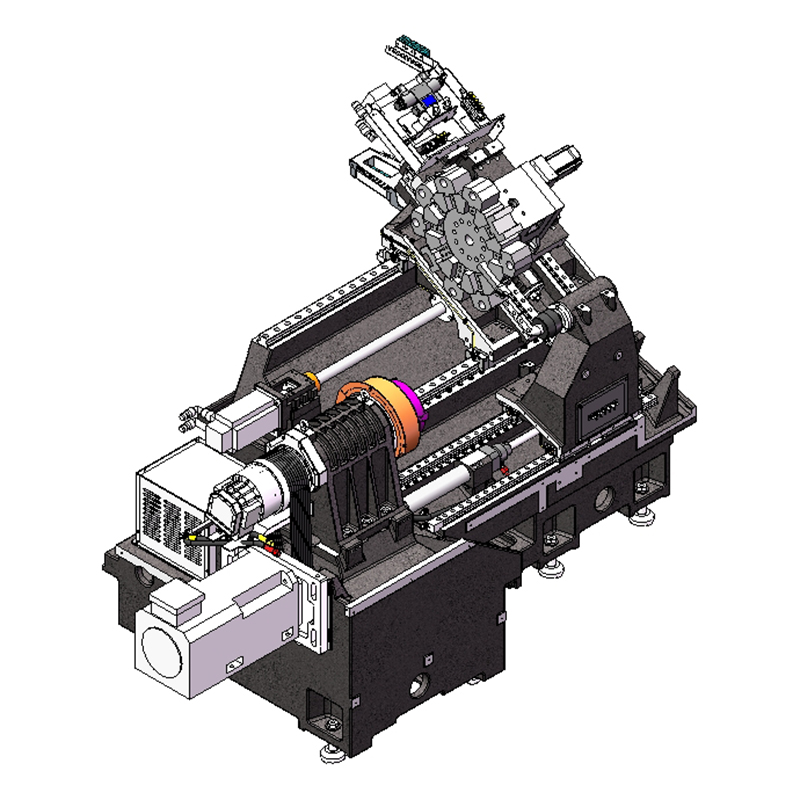

Adopts 30° Machine Bed, High Rigidity with Hydraulic Servo 10 Tool Post Turret, with Servo Spindle, Hydraulic Through Chuck, and Hydraulic Tailstock, suitable for the Heavy Cutting Shaft and Plate Workpiece Processing.

|

Standard |

Optional |

|

1. SIEMENS 808D Advanced Control System |

1. FANUC 0i-TF Plus Control System |

|

2. A2-6 |

2. SIEMENS 828D Basic Control System |

|

3. Servo Spindle |

3. GSK 988TA Absolute Control System |

|

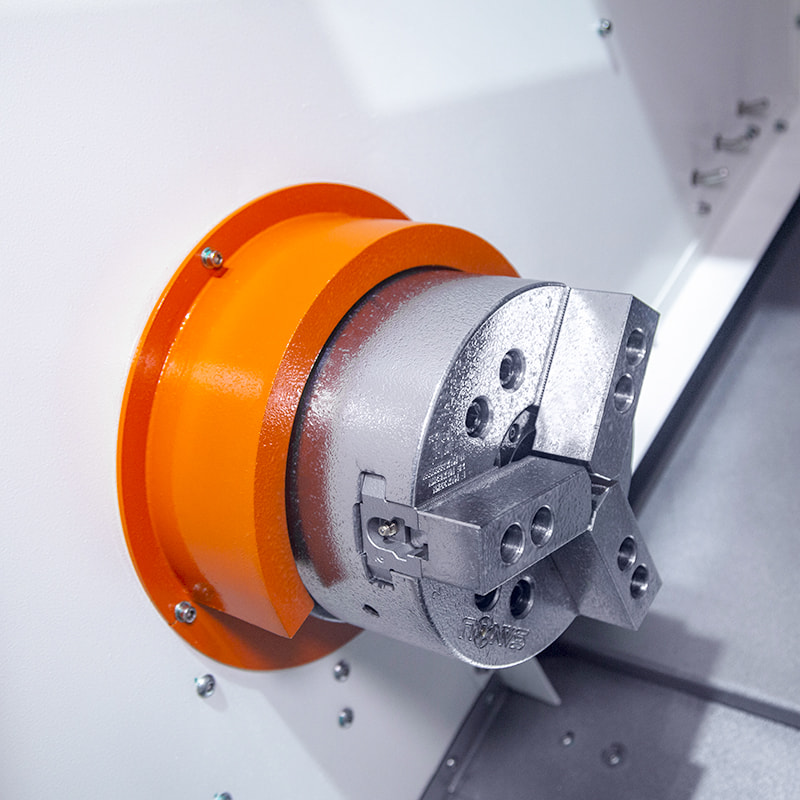

4. Hydraulic Through Chuck 8inch |

4. RENEISHAW Auto Tool Setter |

|

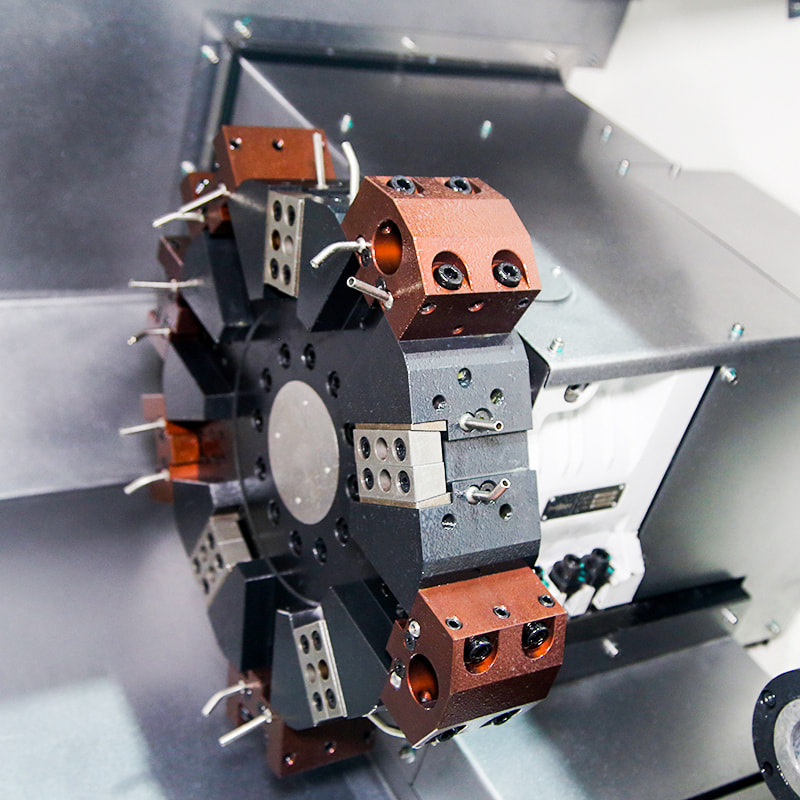

5. Hydraulic Servo 10 Tool Post Turret |

5. 12 Post Driven Tool Turret(BMT55) |

|

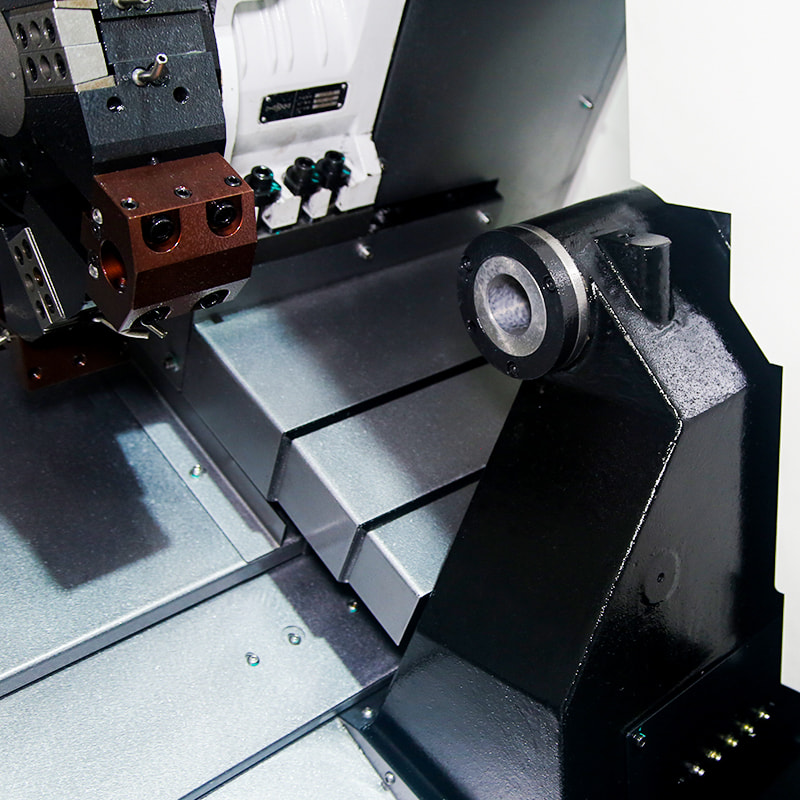

6. Hydraulic Tailstock |

6. Auto Bar Feeder |

|

7. Roller Linear Guideway |

7. Oil Skimmer |

|

8. Chip Conveyor |

Specification

| Configuration | T55 | ||

| Machining Capacity | Maximum Swing Over Bed | φ/mm | 580 |

| Maximum Swing Over Slide | φ/mm | 300 | |

| Maximum Machining Length | mm | 370 | |

| Maximum Machining Diameter | φ/mm | 300 | |

| Maximum Diameter of Bar | φ/mm | 50 | |

| Servo Spindle | Spindle Head Type | GB59001 | A2-6 |

| Spindle Taper Hole | φ/mm | 62 | |

| Spindle Speed Range | r/min | 50-3000 | |

| Spindle Output Torque | N·m | 70 | |

| Main Motor Power | kW | 11 | |

| Chuck Type | Hydraulic Through Chuck | ||

| Chuck Size | inch | 8" | |

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 30 |

| Rapid Traverse Speed On Z-axis | m/min | 30 | |

| Servo Motor Torque On X-axis | N·m | 15 | |

| Servo Motor Torque On Z-axis | N·m | 15 | |

| X-axis Travel | mm | 190 | |

| Z-axis Travel | mm | 400 | |

| Guideway Type | Roller Linear Guideway | ||

| Turret | Turret Type | Hydraulic Servo 10 Tool Post Turret | |

| Tool Size | mm | 25×25/φ32(φ40 as optional) | |

| Tailstock | Tailstock Type | Hydraulic | |

| Tailstock Travel | mm | 320 | |

| Tailstock Sleeve Diameter | φ/mm | 74 | |

| Internal Taper of Tailstock Sleeve | MT5 | ||

| Power Source | Total Rated Power | KVA | 21 |

| Total Rated Current | A | 45 | |

| Dimension | Machine Weight | kg | 3700 |

| Machine Dimension | L*W*H(mm) | 2570×1820×1920 | |

Please note that this parameter and appearance are subject to change without notice, thanks.

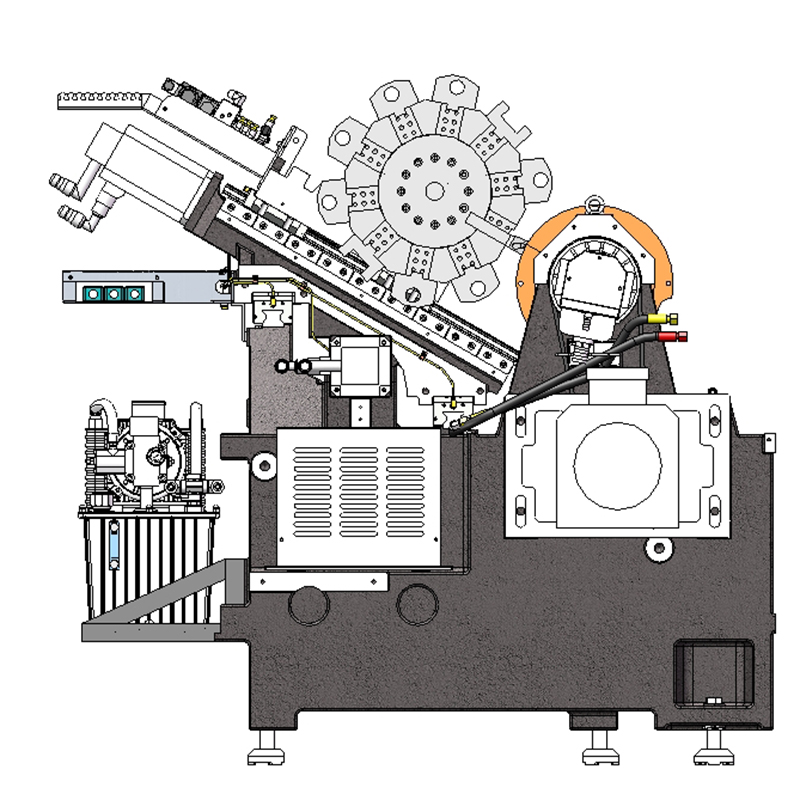

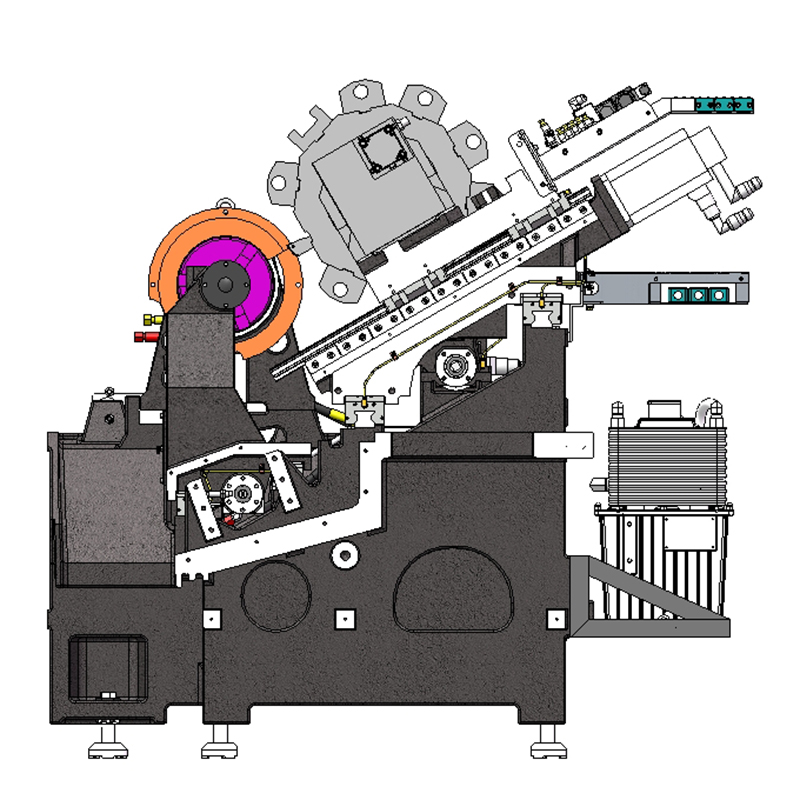

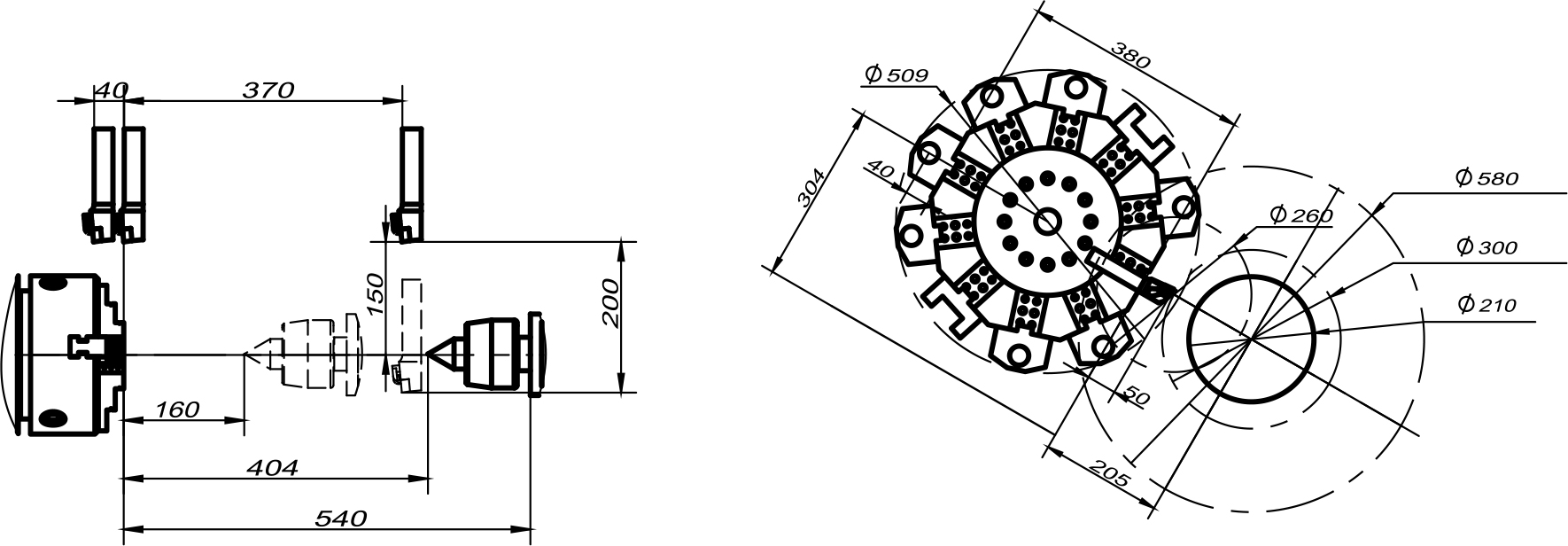

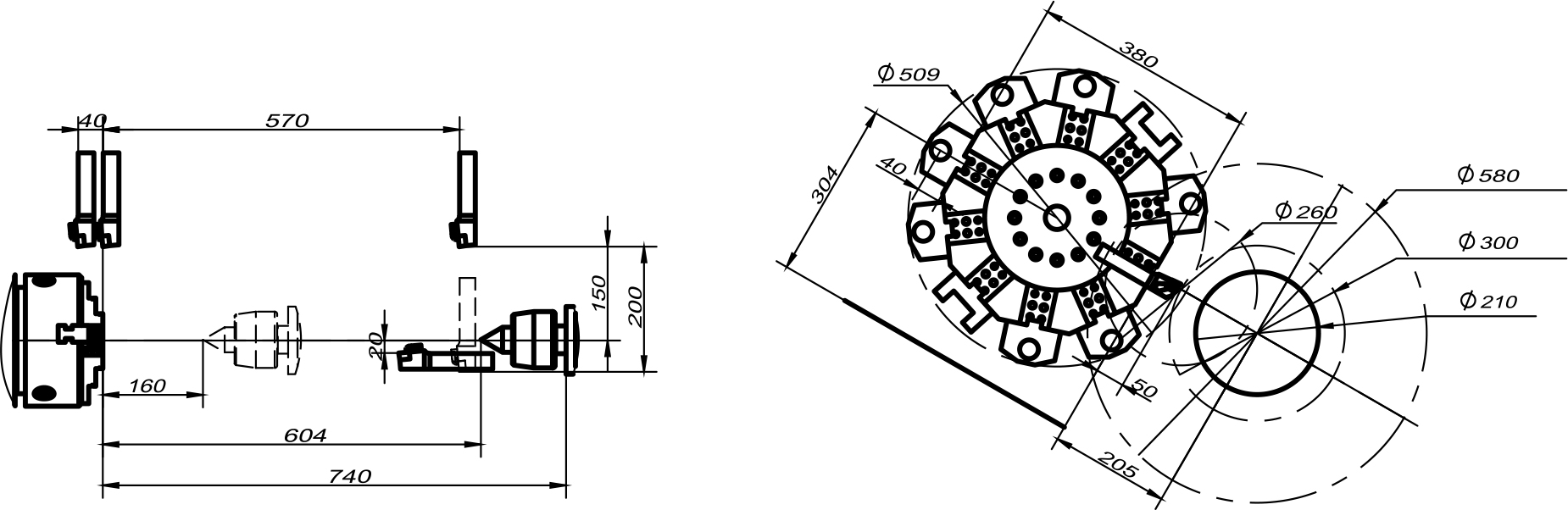

Tool Interferogram

| Configuration | T55L | ||

| Machining Capacity | Maximum Swing Over Bed | φ/mm | 580 |

| Maximum Swing Over Slide | φ/mm | 300 | |

| Maximum Machining Length | mm | 570 | |

| Maximum Machining Diameter | φ/mm | 300 | |

| Maximum Diameter of Bar | φ/mm | 50 | |

| Servo Spindle | Spindle Head Type | GB59001 | A2-6 |

| Spindle Taper Hole | φ/mm | 62 | |

| Spindle Speed Range | r/min | 50-3000 | |

| Spindle Output Torque | N·m | 70 | |

| Main Motor Power | kW | 11 | |

| Chuck Type | Hydraulic Through Chuck | ||

| Chuck Size | inch | 8" | |

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 30 |

| Rapid Traverse Speed On Z-axis | m/min | 30 | |

| Servo Motor Torque On X-axis | N·m | 15 | |

| Servo Motor Torque On Z-axis | N·m | 15 | |

| X-axis Travel | mm | 190 | |

| Z-axis Travel | mm | 600 | |

| Guideway Type | Roller Linear Guideway | ||

| Turret | Turret Type | Hydraulic Servo 10 Tool Post Turret | |

| Tool Size | mm | 25×25/φ32(φ40 as optional) | |

| Tailstock | Tailstock Type | Hydraulic | |

| Tailstock Travel | mm | 520 | |

| Tailstock Sleeve Diameter | φ/mm | 74 | |

| Internal Taper of Tailstock Sleeve | MT5 | ||

| Power Source | Total Rated Power | KVA | 21 |

| Total Rated Current | A | 45 | |

| Dimension | Machine Weight | kg | 4000 |

| Machine Dimension | L*W*H(mm) | 2770×1820×1920 | |

Please note that this parameter and appearance are subject to change without notice, thanks.

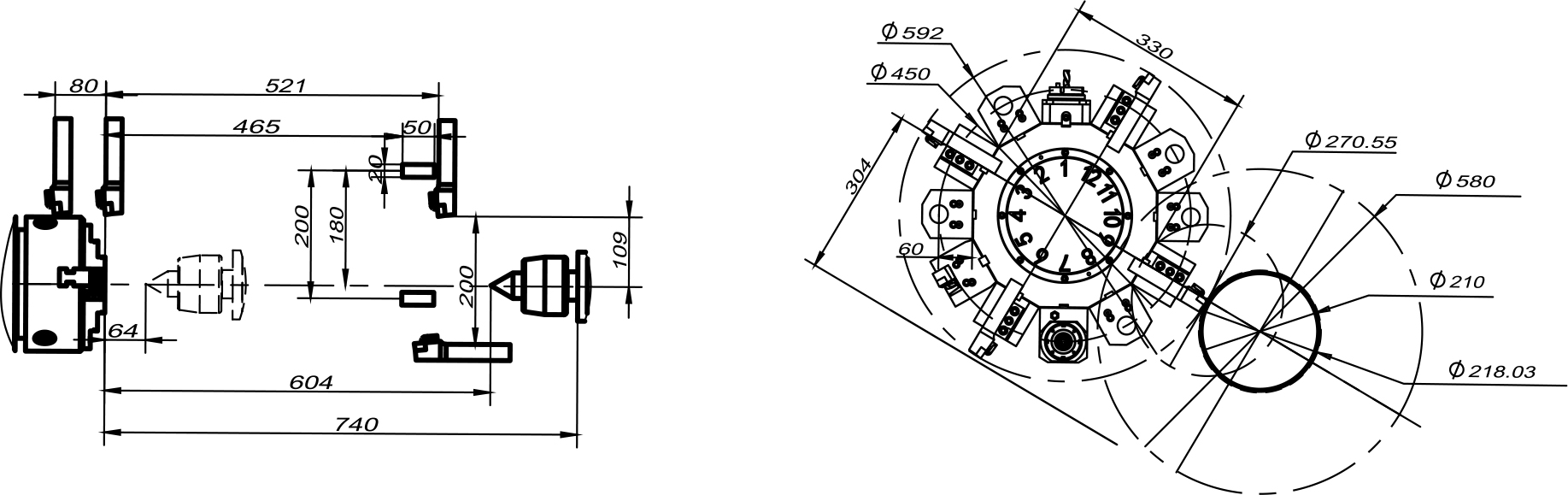

Tool Interferogram

| Configuration | T55M | |||

| Machining Capacity | Maximum Swing Over Bed | φ/mm | 580 | |

| Maximum Swing Over Slide | φ/mm | 300 | ||

| Maximum Machining Length | mm | 320 | 520 | |

| Maximum Machining Diameter | φ/mm | 300 | ||

| Maximum Diameter of Bar | φ/mm | 50 | ||

| Servo Spindle | Spindle Head Type | GB59001 | A2-6 | |

| Spindle Taper Hole | φ/mm | 62 | ||

| Spindle Speed Range | r/min | 50-3000 | ||

| Spindle Output Torque | N·m | 70 | ||

| Main Motor Power | kW | 11 | ||

| Chuck Type | Hydraulic Through Chuck | |||

| Chuck Size | inch | 8" | ||

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 30 | |

| Rapid Traverse Speed On Z-axis | m/min | 30 | ||

| Servo Motor Torque On X-axis | N·m | 15 | ||

| Servo Motor Torque On Z-axis | N·m | 15 | ||

| X-axis Travel | mm | 190 | 190 | |

| Z-axis Travel | mm | 350 | 550 | |

| Guideway Type | Roller Linear Guideway | |||

| Turret | Turret Type | 12 Post Driven Tool Turret (BMT55) | ||

| Tool Size | mm | 25×25/φ40/ER32 | ||

| Tailstock | Tailstock Type | Hydraulic | ||

| Tailstock Travel | mm | 320 | 520 | |

| Tailstock Sleeve Diameter | φ/mm | 74 | ||

| Internal Taper of Tailstock Sleeve | MT5 | |||

| Power Source | Total Rated Power | KVA | 21 | |

| Total Rated Current | A | 45 | ||

| Dimension | Machine Weight | kg | 3700 | 4000 |

| Machine Dimension | L*W*H(mm) | 2570×1820×1920 | 2770×1820×1920 | |

Please note that this parameter and appearance are subject to change without notice, thanks.

Tool Interferogram

RECOMMENDED PRODUCTS

KEEP IN TOUCH

About Us

Taizhou Eastern CNC Technology Co., Ltd.

We are a well-known brand and professional wholesale T55 / T55L / T55M CNC Slant Bed Lathe With High Accuracy of T55 / T55L / T55M CNC Slant Bed Lathe With High Accuracy in China. It is committed to providing professional machine tools and production application solutions to global users, and actively provides customization. It has more than 650 employees. With different models and more than 40 derivative products, we strive to achieve the vision goal of "building a famous brand in the machine tool equipment manufacturing industry".

News

-

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE -

Starting from April 21, 2025, China International Exhibition Center (Shunyi New Venue) was crowded with people, and Eastern CNC Equipment Co., Ltd. became the focus of the whole venue with the theme o...

READ MORE -

Learn about vertical lathes In the tide of the industrial revolution, mechanical manufacturing has continuously broken through the limits, and the birth of vertical lathes is a milestone in the co...

READ MORE -

Automated production lines refer to a series of interconnected processes in which machines and control systems work together to produce products with minimal human intervention. This type of setting...

READ MORE -

China as a global manufacturing power, machine tool industry after decades of development, has formed a number of technology, strength of the enterprises. These enterprises not only occupy an importa...

READ MORE -

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE -

Starting from April 21, 2025, China International Exhibition Center (Shunyi New Venue) was crowded with people, and Eastern CNC Equipment Co., Ltd. became the focus of the whole venue with the theme o...

READ MORE -

Learn about vertical lathes In the tide of the industrial revolution, mechanical manufacturing has continuously broken through the limits, and the birth of vertical lathes is a milestone in the co...

READ MORE -

Automated production lines refer to a series of interconnected processes in which machines and control systems work together to produce products with minimal human intervention. This type of setting...

READ MORE -

China as a global manufacturing power, machine tool industry after decades of development, has formed a number of technology, strength of the enterprises. These enterprises not only occupy an importa...

READ MORE -

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE -

Starting from April 21, 2025, China International Exhibition Center (Shunyi New Venue) was crowded with people, and Eastern CNC Equipment Co., Ltd. became the focus of the whole venue with the theme o...

READ MORE -

Learn about vertical lathes In the tide of the industrial revolution, mechanical manufacturing has continuously broken through the limits, and the birth of vertical lathes is a milestone in the co...

READ MORE

How to buy CNC machine tools

-

01

Contact Us

All of your quotes will be answered within 2 hours by our professional sales support.

-

02

Get A Free Quote

Use reliable parts and components to ensure product quality.

-

03

Fast Delivery

You can expect your order fulfilled within 60 days after placing the order.

-

04

After-sale Support

You can enjoy a one-year many for all of our produons.

Products

Message