All of your quotes will be answered within 2 hours by our professional sales support.

Industry News

Advantages of Multi axis CNC Lathes in Complex Part Machining

2024.11.01

2024.11.01

Industry News

Industry News

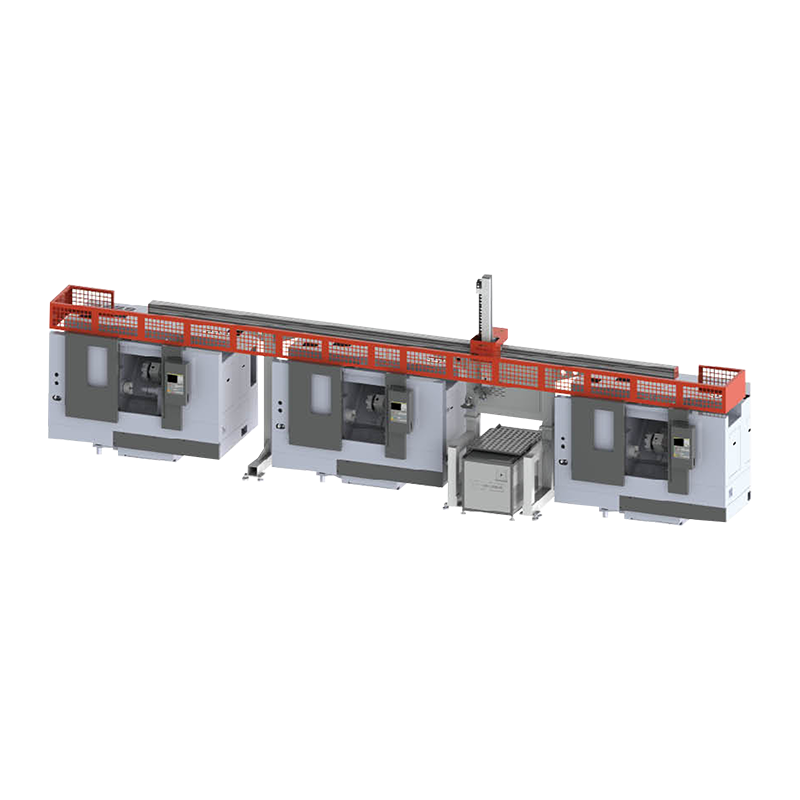

Cheap price multi axis cnc lathe wholesaler

A multi axis CNC lathe is a highly precise metalworking machine that can complete multiple operations in a single setup, significantly enhancing production efficiency and machining accuracy. This article will delve into the advantages of multi axis CNC lathes in complex part machining, helping readers better understand their importance in modern manufacturing.

1. Overview of multi axis CNC Lathes

A multi axis CNC lathe is an advanced machine that integrates multiple spindles and turrets, enabling simultaneous or sequential execution of multiple machining operations. Compared to traditional single-axis lathes, multi axis CNC lathes offer greater flexibility and processing capabilities, making them ideal for complex part machining.

2. Completing Multi-Faceted Operations in a Single Setup

One of significant advantages of a multi axis CNC lathe is its ability to complete multiple facets of machining in a single setup. Traditional single-axis lathes often require multiple setups and repositioning of the workpiece, which increases processing time and the risk of errors. In contrast, a multi axis CNC lathe can perform multiple operations on different surfaces of the workpiece in a single setup, significantly improving efficiency and accuracy.

Reduced Setup Times: By processing multiple surfaces simultaneously, a multi axis CNC lathe reduces the number of setups, minimizing setup errors and enhancing precision.

Shorter Processing Time: Eliminating the need for multiple setups and repositioning reduces overall processing time, resulting in higher productivity.

Enhanced Production Efficiency: The high-efficiency processing capability of a multi axis CNC lathe makes it ideal for batch production and complex part machining.

3. High Precision and Repeatability

Multi axis CNC lathes utilize advanced numerical control technology and high-precision servo drive systems, achieving micron-level machining accuracy and high repeatability. This is particularly important for complex parts that require extremely high dimensional accuracy and surface finish.

Micron-Level Precision: The high-precision servo motors and precision guideways of a multi axis CNC lathe ensure high accuracy, enabling micron-level dimensional control.

High Repeatability: Through precise control by the numerical control system, a multi axis CNC lathe maintains consistent accuracy across multiple machining cycles, ensuring uniform quality in each part.

4. Versatility

A multi axis CNC lathe is highly versatile, capable of performing various machining operations such as turning, drilling, milling, and tapping. This versatility allows a multi axis CNC lathe to meet a wide range of complex part machining requirements.

Turning: A multi axis CNC lathe can perform various turning operations, including internal and external cylindrical turning and face turning, suitable for a variety of shapes and sizes.

Drilling: With multi axis coordination, a multi axis CNC lathe can perform drilling at multiple angles and positions, meeting the drilling needs of complex parts.

Milling: Equipped with milling capabilities, a multi axis CNC lathe can perform planar milling and contour milling, suitable for complex shapes.

Tapping: A multi axis CNC lathe can perform automatic tapping, enhancing machining efficiency and thread quality.

5. Material Flexibility

A multi axis CNC lathe is not limited to metal materials; it can also process plastics, composites, and other non-metallic materials. This broad material flexibility makes a multi axis CNC lathe widely applicable in various industries.

Metal Materials: A multi axis CNC lathe can efficiently process various metals, including steel, aluminum alloys, and copper alloys, suitable for automotive, and mechanical manufacturing.

Non-Metal Materials: A multi axis CNC lathe can also process plastics and composites, suitable for electronics, medical, and consumer goods industries.

6. Intelligence and Automation

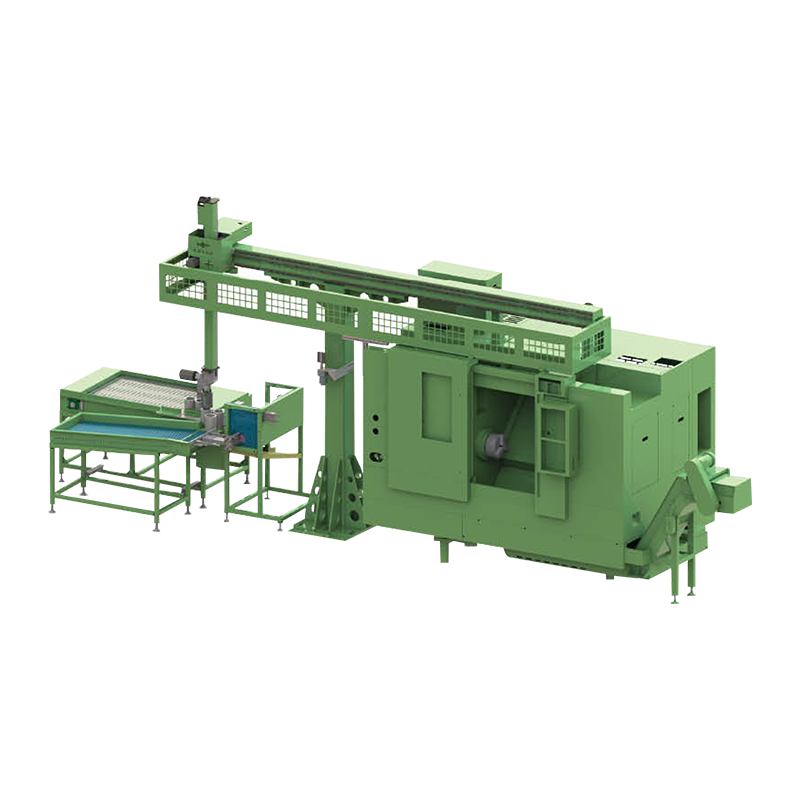

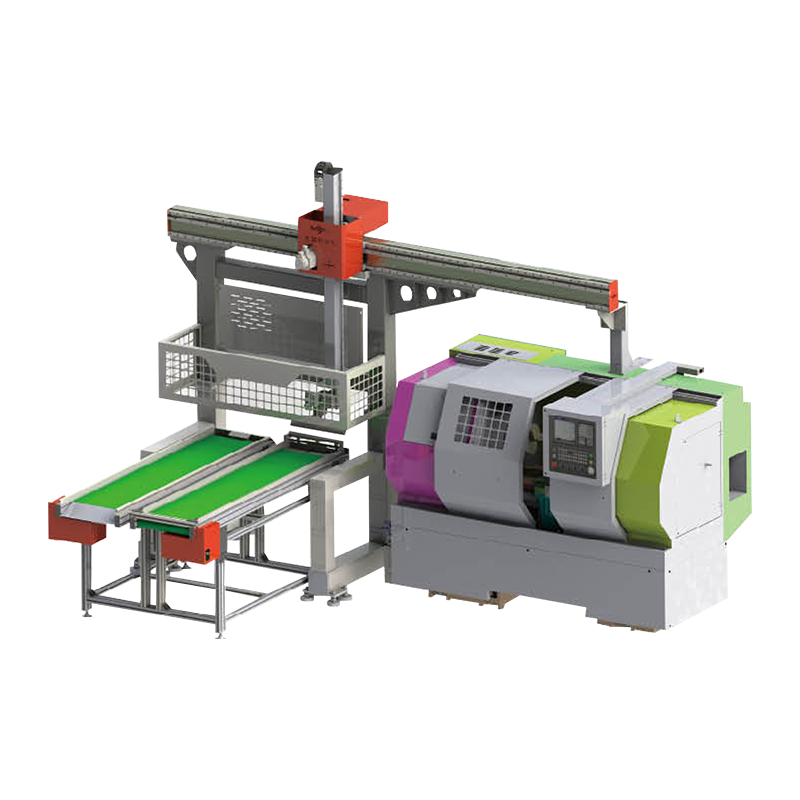

Multi axis CNC lathes are typically equipped with advanced intelligent and automated features, such as automatic loading and unloading systems, tool presetters, and online inspection systems. These features enhance production efficiency and ensure machining quality.

Automatic Loading and Unloading Systems: A multi axis CNC lathe can be equipped with automatic loading and unloading systems to achieve unmanned production, significantly increasing production efficiency.

Tool Presetters: Using a tool presetter, operators can pre-calibrate tools to ensure their installation accuracy and machining quality.

Online Inspection Systems: A multi axis CNC lathe can be equipped with online inspection systems to monitor dimensions and shapes in real-time, promptly identifying and correcting errors.

7. Applicable Industries

Multi axis CNC lathes find extensive applications in various industries, particularly those requiring high-precision and high-efficiency machining.

Automotive Manufacturing: A multi axis CNC lathe can efficiently process engine components, transmission parts, and other complex parts, improving production efficiency and quality in the automotive industry.

Medical Equipment: A multi axis CNC lathe can process precision components for medical devices, ensuring the high performance and reliability of medical equipment.

Electronics Manufacturing: A multi axis CNC lathe can process precision parts for electronic products, such as enclosures and connectors, meeting the high-precision requirements of the electronics industry.

Summary

Multi axis CNC lathes offer significant advantages in complex part machining, including the ability to complete multi-faceted operations in a single setup, high precision, versatility, material flexibility, intelligence, and automation. These advantages make multi axis CNC lathes indispensable in modern manufacturing, particularly in industries requiring high-precision and high-efficiency machining. We hope this article helps you understand the processing capabilities of multi axis CNC lathes.

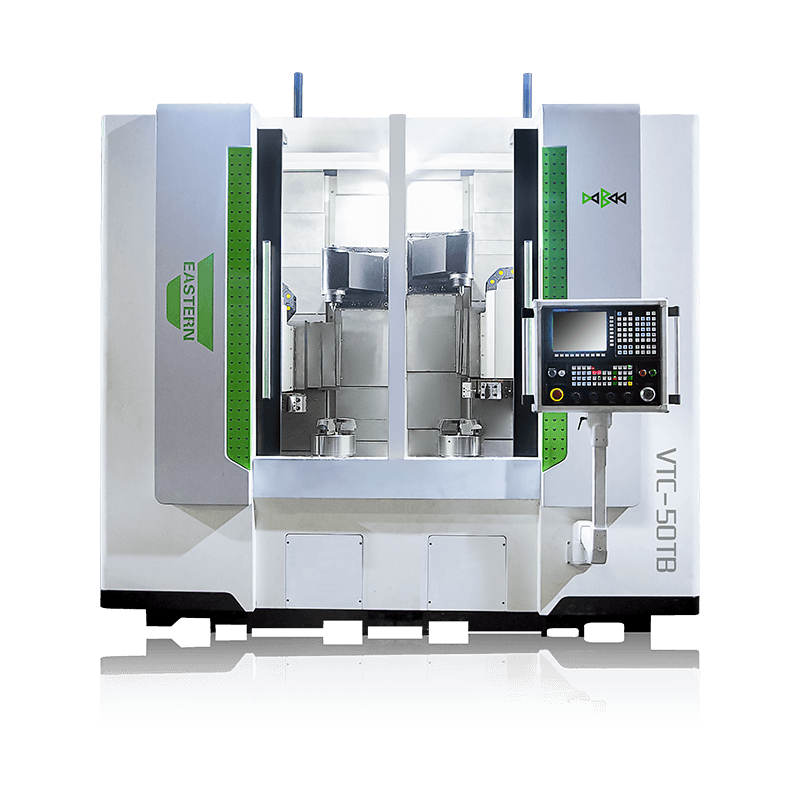

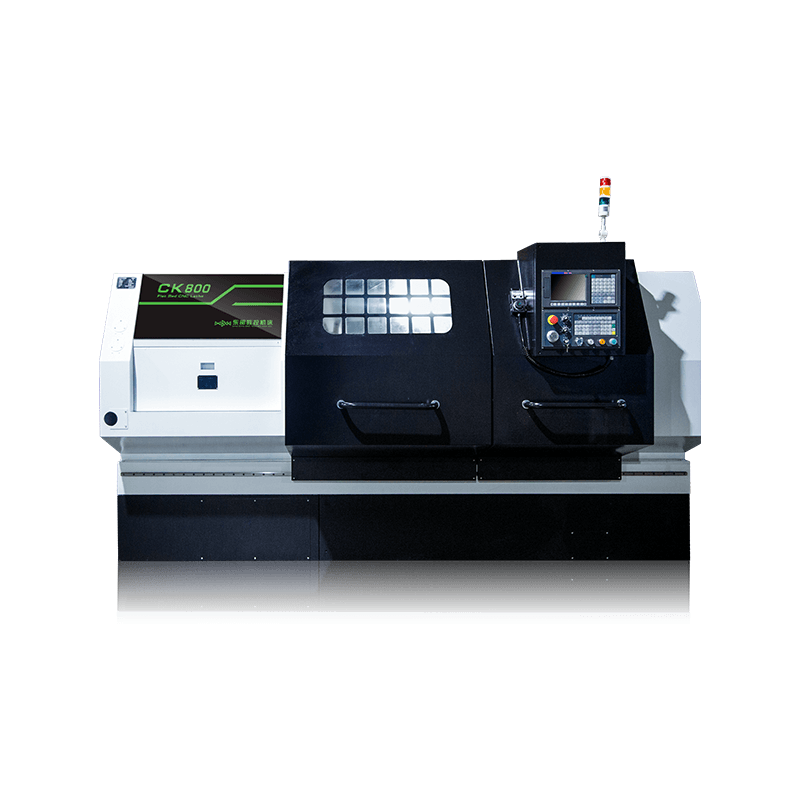

RECOMMENDED PRODUCTS

How to buy CNC machine tools

-

01

Contact Us

-

02

Get A Free Quote

Use reliable parts and components to ensure product quality.

-

03

Fast Delivery

You can expect your order fulfilled within 60 days after placing the order.

-

04

After-sale Support

You can enjoy a one-year many for all of our produons.

Products

Message