When selecting the right Twin Spindle Lathe Factory, several crucial factors should be taken into account. These factors directly impact production efficiency, product quality, and long-term operating costs. Below are the key elements you should consider when choosing a Twin Spindle Lathe Supplier:

1. Technical Capabilities and Innovation

Technical capabilities are among the important factors when selecting a Twin Spindle Lathe Factory. A reliable supplier should have advanced design and manufacturing capabilities and provide innovative technical solutions. As twin spindle lathes are high-precision, high-efficiency machines, the supplier's technological expertise will determine the equipment's reliability and processing accuracy.

It's important to evaluate whether the supplier has in-house developed technologies and can offer customized solutions tailored to your specific requirements.

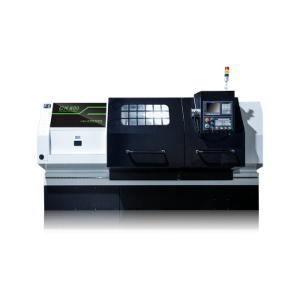

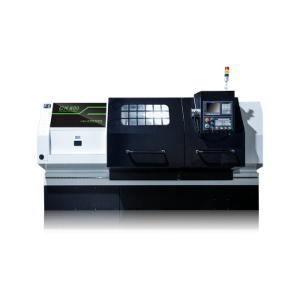

CK800 / CK800L Horizontal CNC Flat Bed Lathe

2. Equipment Stability and Quality Control

The stability of the equipment and the supplier's quality control systems are vital considerations. Twin spindle lathes are designed to operate under heavy loads for extended periods, and their stability is key to maintaining consistent production efficiency and product quality.

Choosing a supplier with stringent quality control processes is crucial. Check for certifications, testing standards, and the final inspection of machines before delivery to ensure that the equipment will perform optimally over time.

3. After-Sales Service and Technical Support

After-sales service is another critical factor when evaluating a Twin Spindle Lathe Supplier. A reliable supplier should offer comprehensive after-sales support, including regular maintenance, technical upgrades, and emergency repair services.

Timely technical support and service ensure minimal downtime and keep production running smoothly, which is essential for reducing operational costs caused by machine failures.

4. Pricing and Cost-Effectiveness

While pricing should not be the sole deciding factor, it plays a significant role in the selection process. A trustworthy Twin Spindle Lathe Factory should offer competitive prices and provide value-for-money solutions.

In addition to initial pricing, consider the long-term operational costs, including maintenance, consumables, and potential downtime due to equipment malfunctions.

5. Customer References and Reputation

The reputation of the Twin Spindle Lathe Supplier can be gauged through customer testimonials and case studies. A well-established supplier with a strong market presence is likely to deliver reliable products and services.

Look for feedback from other clients to assess the quality of the products, after-sales service, and the supplier's overall reliability in the market.

6. Production Capacity and Delivery Times

Understanding the supplier's production capacity and delivery timelines is essential to ensure they can meet your manufacturing needs. Ensure that the supplier can meet delivery deadlines and offer adequate production support.

Delays in delivery can cause to production bottlenecks, so a supplier with a well-managed supply chain is vital for maintaining timely operations.

7. Customization Capabilities

Some industries require specific customization of twin spindle lathes to meet unique production needs. Choosing a supplier that offers customization services ensures that your equipment will be tailored to your precise requirements, improving production efficiency.

Suppliers with strong customization capabilities can offer you flexibility in machine design, tooling, and features to enhance your production capabilities.

Choosing the right Twin Spindle Lathe Factory is essential for ensuring high productivity, minimizing downtime, and improving product quality. By considering factors like technical capabilities, equipment stability, after-sales service, pricing, and customization, you can make an informed decision and select a supplier that will support your manufacturing goals for the long term.