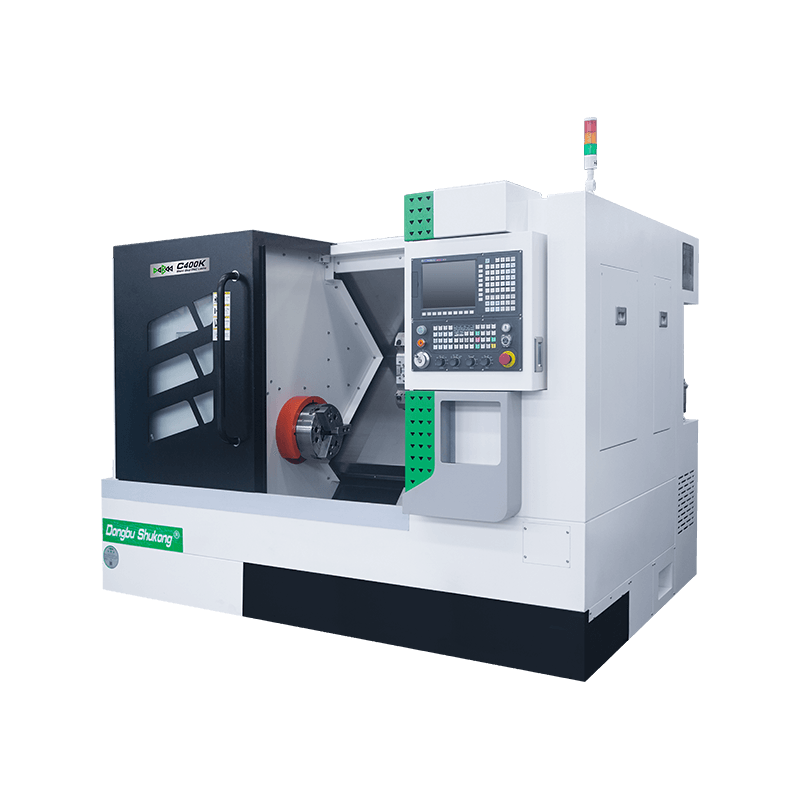

OEM C400K CNC Slant Bed Lathe with High Accuracy Supplier

C400K CNC Slant Bed Lathe with High Accuracy

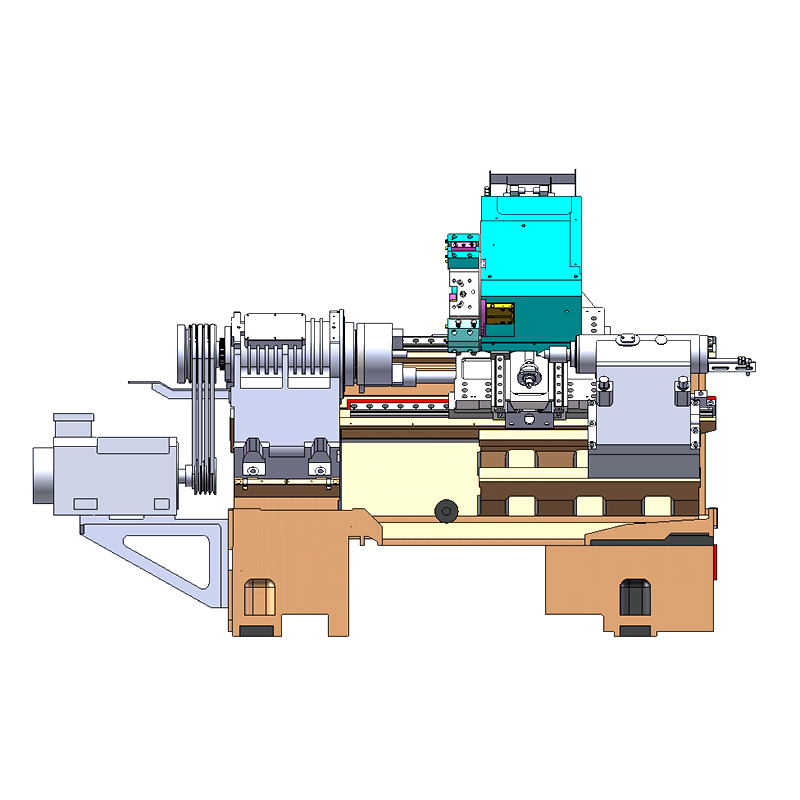

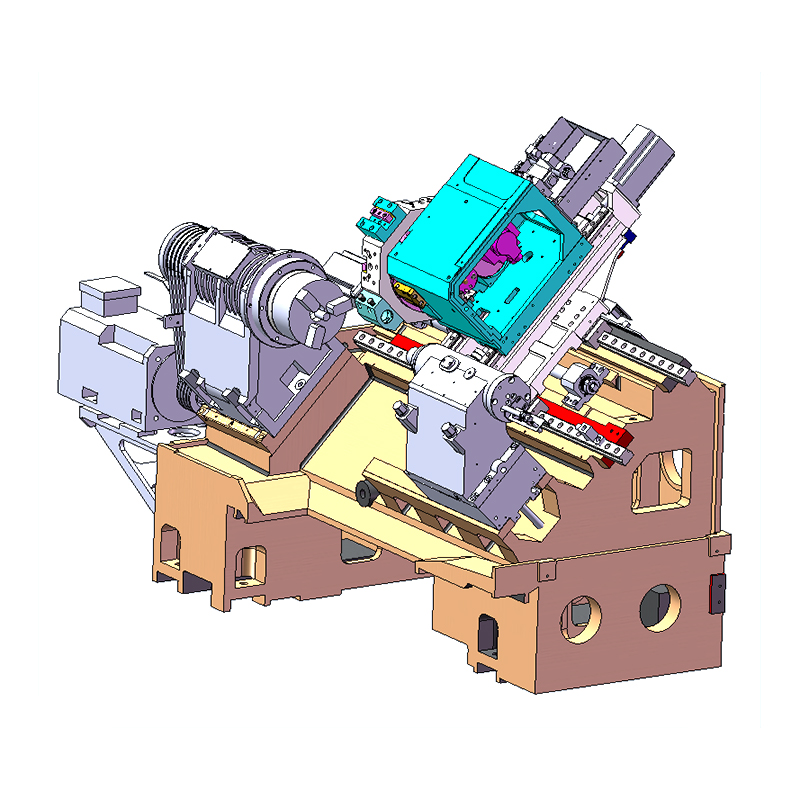

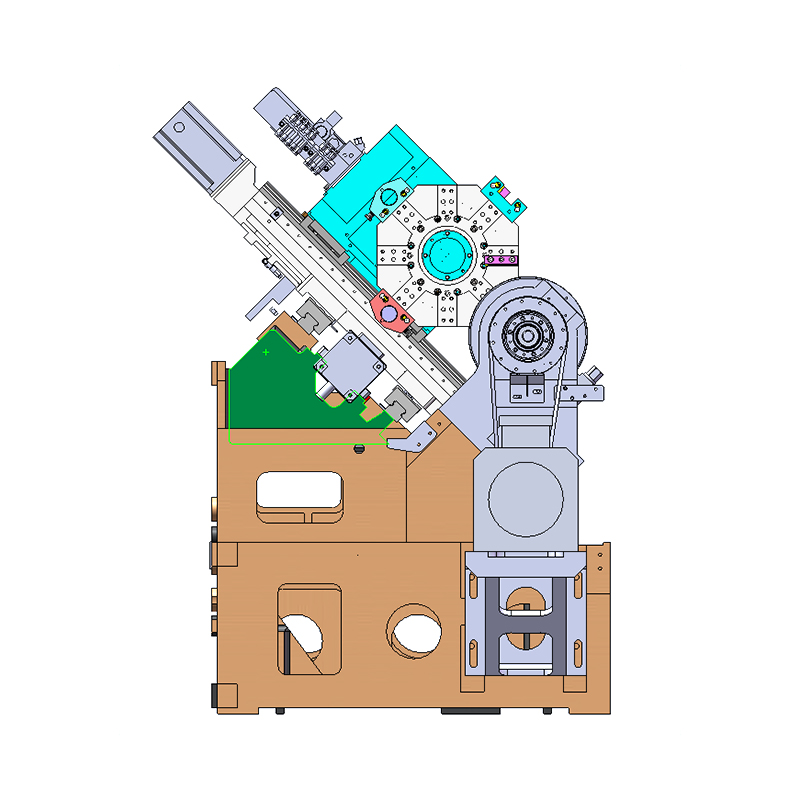

C400K CNC Slant Bed Lathe With High Accuracy adopts an integrated 45° inclined bed and circular cavity cast iron structure to ensure heavy cutting capabilities. The bed is cast with high-quality resin sand, which has good rigidity, good shock resistance, and smooth chip removal. The spindle box bearing adopts double row cylindrical roller bearings and bidirectional thrust angular contact bearings, which have high rigidity. The heat dissipation adopts a corresponding structural design to reduce the thermal deformation of the spindle, so that the spindle can maintain the relative stability of the spindle axis during long-term operation. C400K CNC Slant Bed Lathe With High Accuracy series full-function lathes are equipped with 8-12 servo hydraulic turrets. Fast indexing and positioning, high indexing accuracy. Good turning rigidity. The tool turret has a water outlet function in the center of the tool, and the water outlet pressure is high. The water tank that provides central water outlet has sufficient capacity, and there will be no flow interruption during the processing. It is equipped with a filtration system and has high filtration accuracy.

|

|

Maximum Machining Diameter: 320mm |

|

|

Maximum Machining Length: 450mm |

|

|

Chuck Size: 8" inch |

-

DETAIL PARAMETERS

-

VIDEO DISPLAY

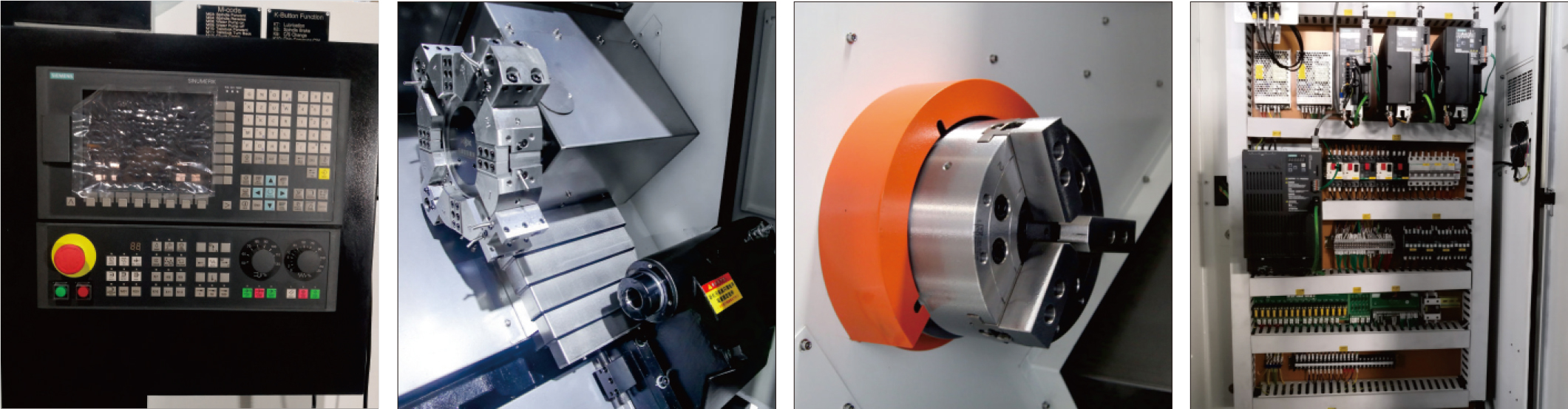

1. The lathe uses an hydraulic servo turret with high positioning accuracy, fast tool change time, and minimal deformation under heavy cutting.

2. The transmission system uses linear roller guideways imported from Taiwan to meet the requirements of high speed and high efficiency. It reduces friction resistance and deformation caused by temperature rise, improves the machining accuracy, and ensures the long-term stability of the cutting machining accuracy.

3. Integral fully-enclosed protection makes it durable, with stable operation and low noise. It is superior to similar products in terms of waterproofing, oil drainage, dustproofing and safety performance.

4. The machine with an electrical cabinet has good sealing performance and uses the heat exchanger to ensure normal operation in a high-temperature and high-humidity environment.

5. The chip conveyor (optional) has the advantages of smooth chip removal, compact size, high efficiency, stable delivery, low noise, and overload protection, etc.

|

Spindle Spindle Speed: 3000rpm;2500rpm Headstock |

|

|

45° Integrally Slant Bed Structure Casting Structure |

| Integrated Pallet The integrated design of the motor base and the slide plate features excellent strength, which reduces the assembly precision error and ensures the machine's precision. X/Z-axis Travel: 200/500mm; 200/1100mm X/Z-axis Rapid Traverse Speed: 20/25m/min |

|

Feature:

Adopts 45° Machine Bed, High Rigidity with Hydraulic Servo 8/12 Tool Post Turret, with Servo Spindle, Hydraulic Through Chuck, and Hydraulic Tailstock, suitable for the Heavy Cutting Shaft and Plate Workpiece Processing.

|

Standard |

Optional |

|

1. SIEMENS 808D Advanced Control System |

1. FANUC 0i-TF Plus Control System |

|

2. A2-6 |

2. SIEMENS 828D Basic Control System |

|

3. Servo Spindle |

3. SYNTEC 22TB Control System |

|

4. Hydraulic Through Chuck 8inch |

4. GSK 988TA Absolute Control System |

|

5. Hydraulic Servo 8/12 Tool Post Turret |

5. Built-in Spindle, Max 4000rpm |

|

6. Hydraulic Tailstock |

6. Spindle Head Type A2-8 |

|

7. Roller Linear Guideway |

7. 12 Post Driven Tool Turret(BMT45) |

|

8. Hydraulic Through Chuck 8inch |

|

|

9. RENEISHAW Auto Tool Setter |

|

|

10. Auto Bar Feeder |

|

|

11. Oil Skimmer |

|

|

12. Chip Conveyor |

|

|

13. Servo Programmable Tailstock(Tailstock Travel: 280mm) |

Specification

| Configuration | C400K | |||

| Machining Capacity | Maximum Swing Over Bed | φ/mm | 400 | |

| Maximum Swing Over Slide | φ/mm | 250 | ||

| Maximum Machining Length | mm | 450 | Optional 420 | |

| Maximum Machining Diameter | φ/mm | 320 | ||

| Maximum Diameter of Bar | φ/mm | 50 | Optional 74 | |

| Servo Spindle | Spindle Head Type | GB59001 | A2-6 | Optional A2-8 |

| Spindle Taper Hole | φ/mm | 62 | Optional 86 | |

| Spindle Speed Range | r/min | 50-3000 | Optional 50-2500 | |

| Spindle Shift Mode | Servo | |||

| Spindle Output Torque | N·m | 150 | ||

| Main Motor Power | kW | 11 | ||

| Chuck Type | Hydraulic Through Chuck | |||

| Chuck Size | inch | 8" | Optional 10 | |

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 20 | |

| Rapid Traverse Speed On Z-axis | m/min | 25 | ||

| Servo Motor Torque On X-axis | N·m | 7.5 | ||

| Servo Motor Torque On Z-axis | N·m | 7.5 | ||

| X-axis Travel | mm | 200 | ||

| Z-axis Travel | mm | 500 | Optional 425 | |

| Guideway Type | Roller Linear Guideway | |||

| Turret | Turret Type | Hydraulic Servo 8/12 Tool Post Turret | ||

| Turning Tools/Boring Bar Size | mm | 25×25/φ32 | ||

| Tailstock | Tailstock Type | Hydraulic | ||

| Tailstock Sleeve Diameter | φ/mm | 88 | ||

| Tailstock Travel | mm | 80 | ||

| Internal Taper of Tailstock Sleeve | MT5 | |||

| Power Source | Total Rated Power | KVA | 18 | |

| Total Rated Current | A | 35 | ||

| Dimension | Machine Weight | kg | 3500 | Optional 3550 |

| Machine Dimension | L*W*H(mm) | 2620×1880×1870 | ||

Please note that this parameter and appearance are subject to change without notice, thanks.

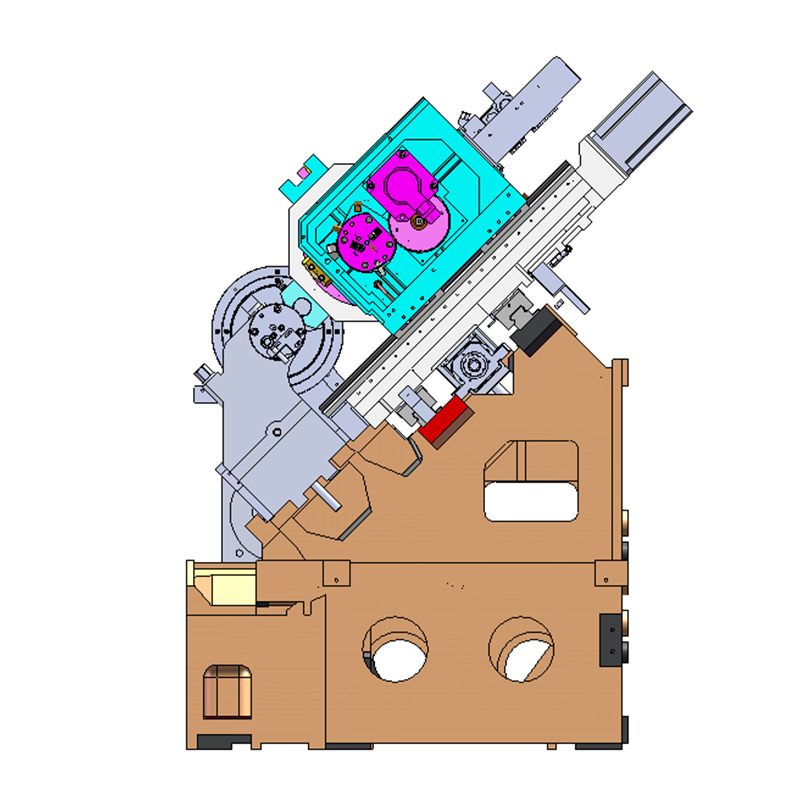

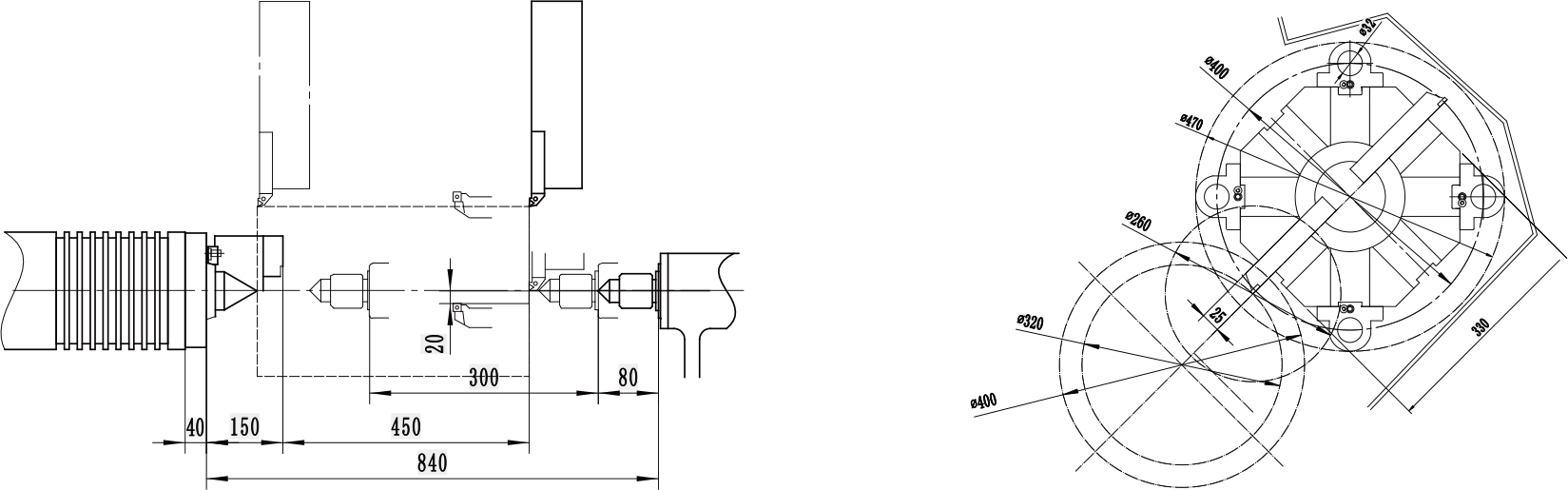

Tool Interferogram

| Machining Capacity | Configuration | C400KA2-6(with Driven Tool Turret) | ||

| Maximum Swing Over Bed | φ/mm | 400 | ||

| Maximum Swing Over Slide | φ/mm | 250 | ||

| Maximum Machining Length | mm | 340 | Optional 315 | |

| Maximum Machining Diameter | φ/mm | 320 | ||

| Maximum Diameter of Bar | φ/mm | 50 | ||

| Servo Spindle | Spindle Head Type | GB59001 | A2-6 | |

| Spindle Taper Hole | φ/mm | 62 | ||

| Spindle Speed Range | r/min | 50-3000 | ||

| Spindle Shift Mode | Servo | |||

| Spindle Output Torque | N·m | 150 | ||

| Main Motor Power | kW | 11 | ||

| Chuck Type | Hydraulic Through Chuck | |||

| Chuck Size | inch | 8" | Optional 10' | |

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 20 | |

| Rapid Traverse Speed On Z-axis | m/min | 25 | ||

| Servo Motor Torque On X-axis | N·m | 7.5 | ||

| Servo Motor Torque On Z-axis | N·m | 7.5 | ||

| X-axis Travel | mm | 150 | ||

| Z-axis Travel | mm | 400 | Optional 37 | |

| Guideway Type | Roller Linear Guideway | |||

| Turret | Turret Type | 12 Post Driven Tool Turret (BMT45) | ||

| Turning Tools/Boring Bar Size | mm | 20×20/φ32/ER25 | ||

| Tailstock | Tailstock Type | Hydraulic | ||

| Tailstock Sleeve Diameter | φ/mm | 88 | ||

| Tailstock Sleeve Travel | mm | 80 | ||

| Internal Taper of Tailstock Sleeve | MT5 | |||

| Power Source | Total Rated Power | KVA | 18 | |

| Total Rated Current | A | 35 | ||

| Dimension | Machine Weight | kg | 3550 | Optional 360C |

| Machine Dimension | L*W*H(mm) | 2620×1880×1870 | ||

Please note that this parameter and appearance are subject to change without notice, thanks.

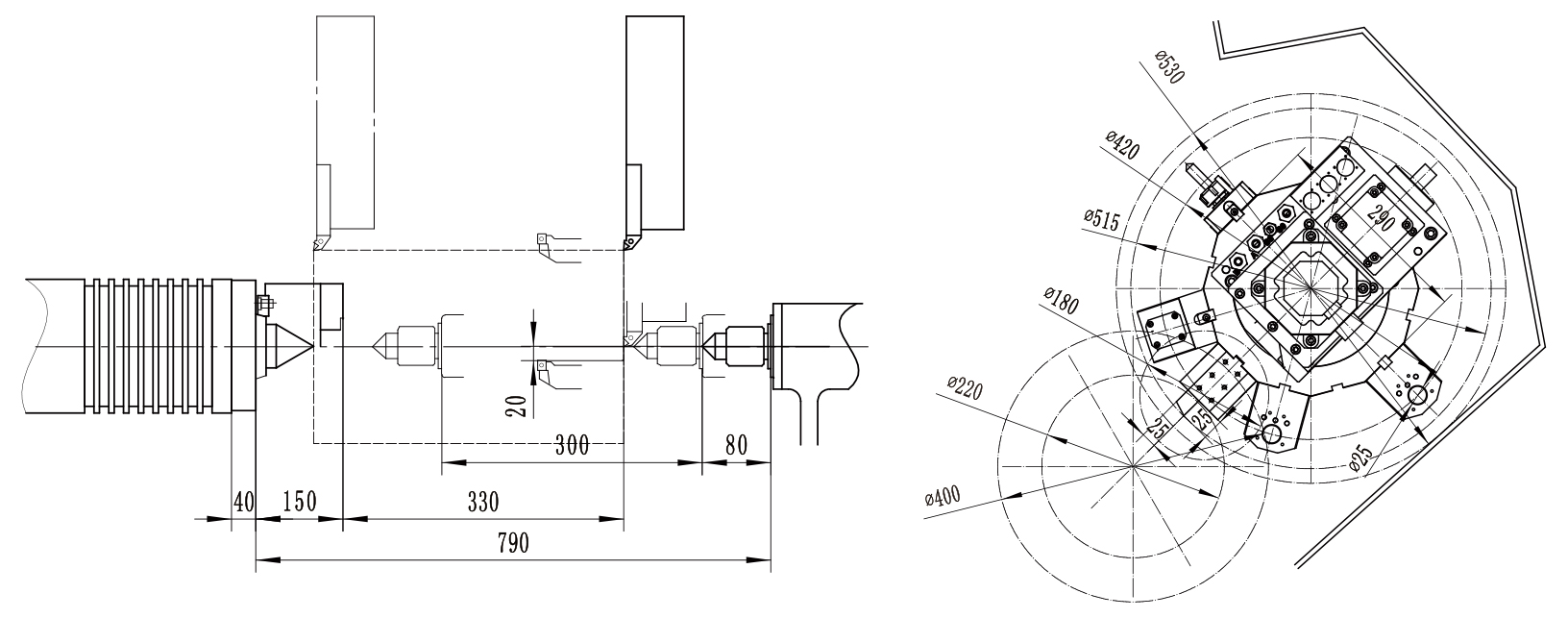

Tool Interferogram

| Configuration | C400KA2-8(with Driven Tool Turret) | ||

| Machining Capacity | Maximum Swing Over Bed | φ/mm | 400 |

| Maximum Swing Over Slide | φ/mm | 250 | |

| Maximum Machining Length | mm | 315 | |

| Maximum Machining Diameter | φ/mm | 320 | |

| Maximum Diameter of Bar | φ/mm | 74 | |

| Servo Spindle | Spindle Head Type | GB59001 | A2-8 |

| Spindle Taper Hole | φ/mm | 86 | |

| Spindle Speed Range | r/min | 50-2500 | |

| Spindle Shift Mode | Servo | ||

| Spindle Output Torque | N·m | 150 | |

| Main Motor Power | kW | 11 | |

| Chuck Type | Hydraulic Through Chuck | ||

| Chuck Size | inch | 10" | |

| Feed Rate | Rapid Traverse Speed On X-axis | m/min | 20 |

| Rapid Traverse Speed On Z-axis | m/min | 25 | |

| Servo Motor Torque On X-axis | N·m | 7.5 | |

| Servo Motor Torque On Z-axis | N·m | 7.5 | |

| X-axis Travel | mm | 150 | |

| Z-axis Travel | mm | 375 | |

| Guideway Type | Roller Linear Guideway | ||

| Turret | Turret Type | 12 Post Driven Tool Turret (BMT45) | |

| Turning Tools/Boring Bar Size | mm | 20×20/φ32/ER25 | |

| Tailstock | Tailstock Type | Hydraulic | |

| Tailstock Sleeve Diameter | φ/mm | 88 | |

| Tailstock Sleeve Travel | mm | 80 | |

| Internal Taper of Tailstock Sleeve | MT5 | ||

| Power Source | Total Rated Power | KVA | 18 |

| Total Rated Current | A | 35 | |

| Dimension | Machine Weight | kg | 3630 |

| Machine Dimension | L*W*H(mm) | 2620×1880×1870 | |

Please note that this parameter and appearance are subject to change without notice, thanks.

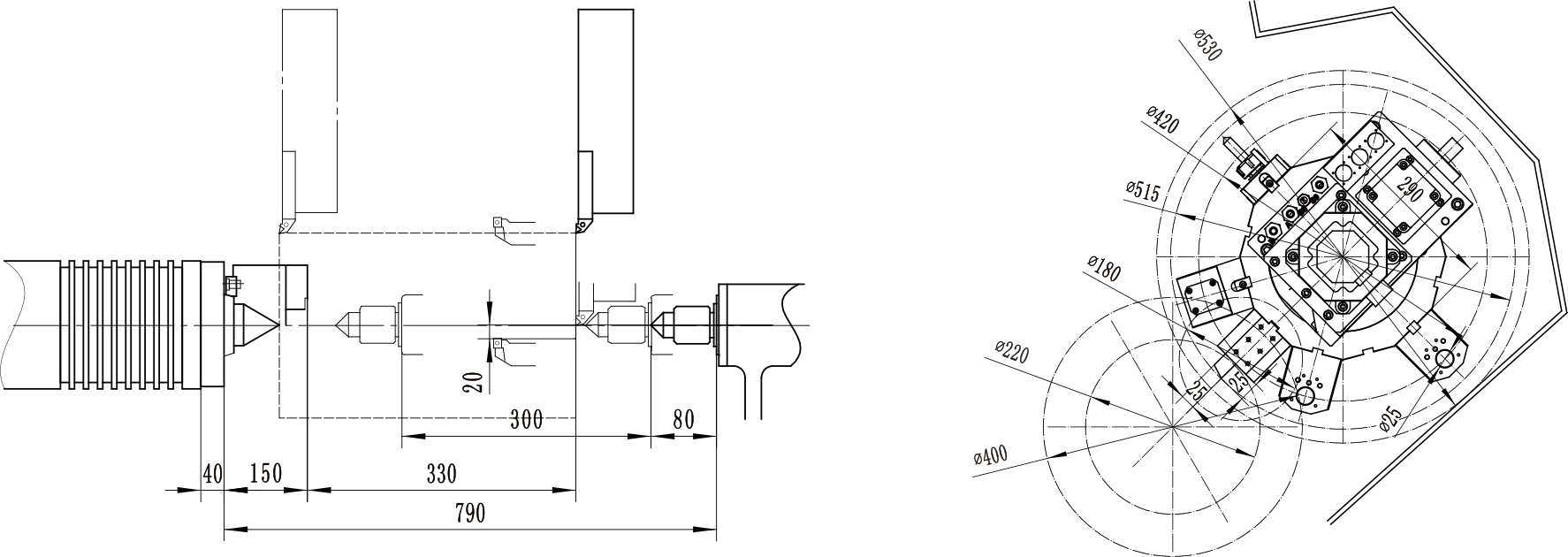

Tool Interferogram

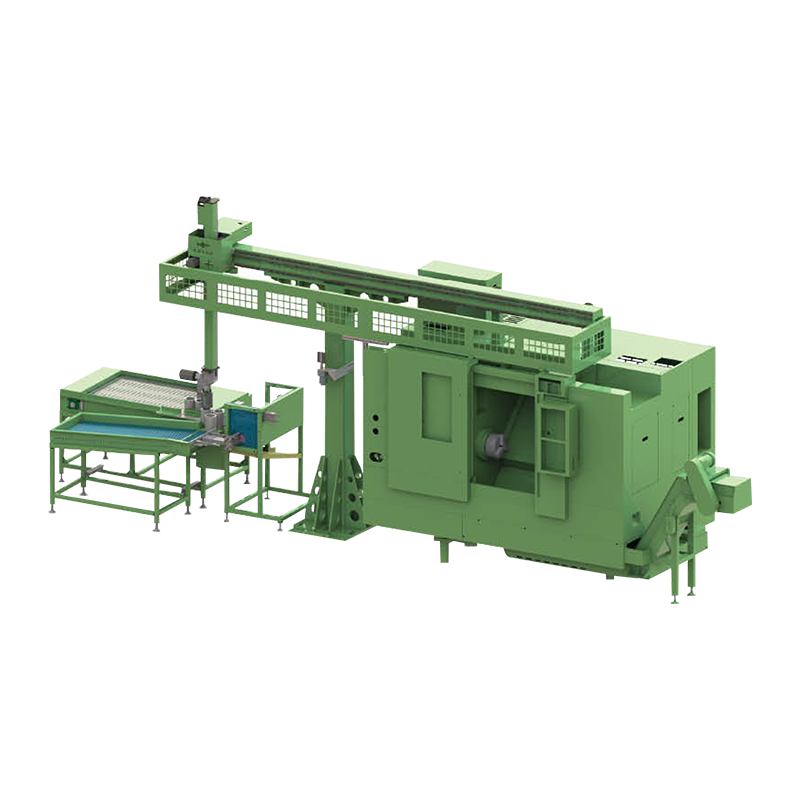

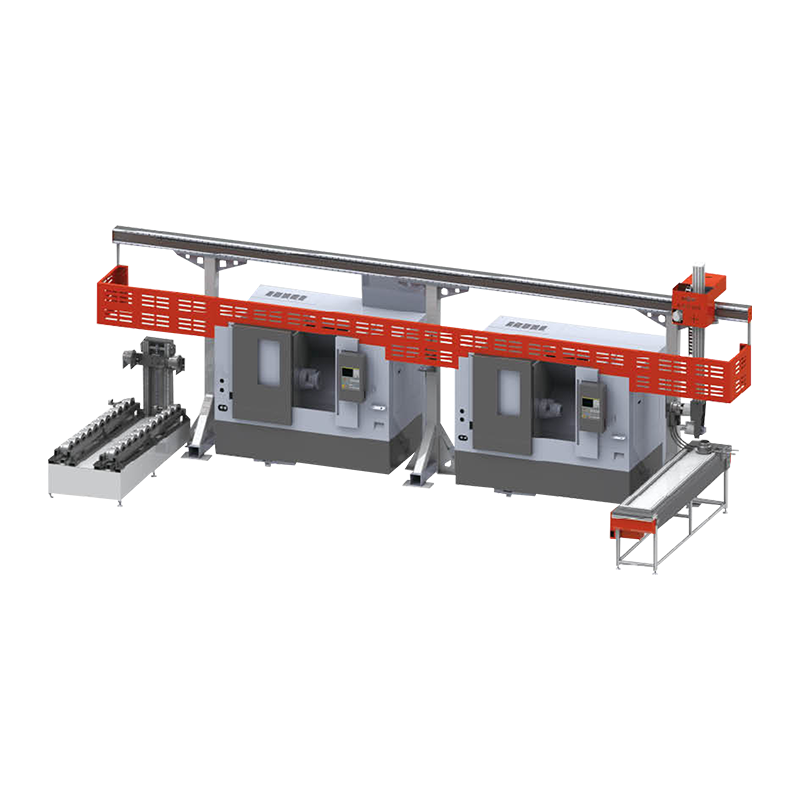

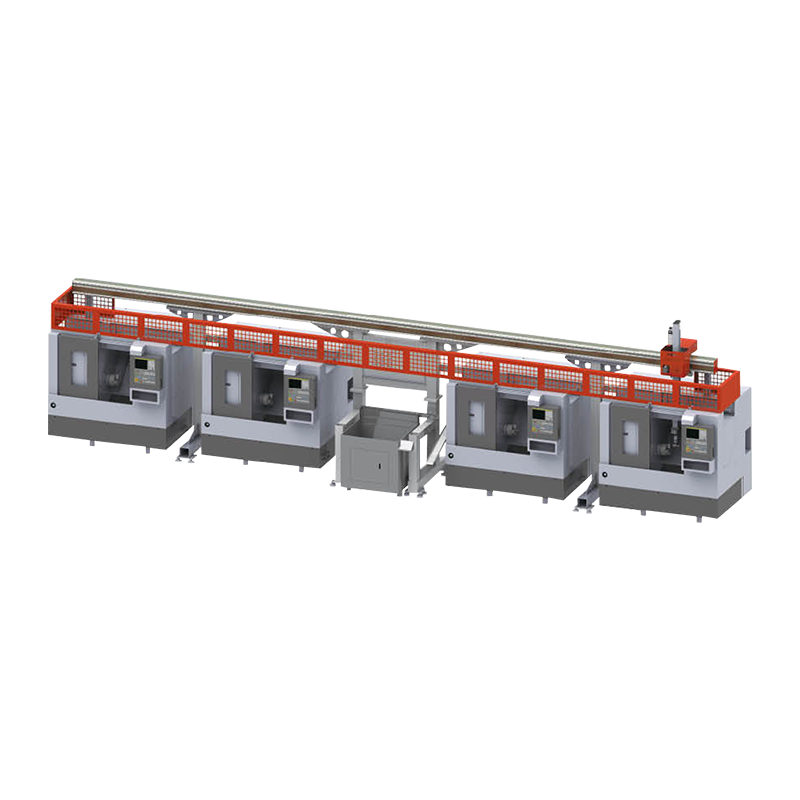

RECOMMENDED PRODUCTS

KEEP IN TOUCH

About Us

Taizhou Eastern CNC Technology Co., Ltd.

We are a well-known brand and professional wholesale C400K CNC Slant Bed Lathe with High Accuracy of C400K CNC Slant Bed Lathe with High Accuracy in China. It is committed to providing professional machine tools and production application solutions to global users, and actively provides customization. It has more than 650 employees. With different models and more than 40 derivative products, we strive to achieve the vision goal of "building a famous brand in the machine tool equipment manufacturing industry".

News

-

Automated production lines refer to a series of interconnected processes in which machines and control systems work together to produce products with minimal human intervention. This type of setting...

READ MORE -

China as a global manufacturing power, machine tool industry after decades of development, has formed a number of technology, strength of the enterprises. These enterprises not only occupy an importa...

READ MORE -

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE -

Vertical turning centers have become an integral part of modern manufacturing processes due to their high precision, versatility and efficiency. Designed to perform a variety of operations on a vert...

READ MORE -

VTM500 series Vertical Lathe machine adopts six-axis and five-linkage layout of T-shape structure, the Vertical Lathe machine is equipped with six servo axes X, Y, Z1, Z2, B, C, as well as eight-stat...

READ MORE -

Automated production lines refer to a series of interconnected processes in which machines and control systems work together to produce products with minimal human intervention. This type of setting...

READ MORE -

China as a global manufacturing power, machine tool industry after decades of development, has formed a number of technology, strength of the enterprises. These enterprises not only occupy an importa...

READ MORE -

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE -

Vertical turning centers have become an integral part of modern manufacturing processes due to their high precision, versatility and efficiency. Designed to perform a variety of operations on a vert...

READ MORE -

VTM500 series Vertical Lathe machine adopts six-axis and five-linkage layout of T-shape structure, the Vertical Lathe machine is equipped with six servo axes X, Y, Z1, Z2, B, C, as well as eight-stat...

READ MORE -

Automated production lines refer to a series of interconnected processes in which machines and control systems work together to produce products with minimal human intervention. This type of setting...

READ MORE -

China as a global manufacturing power, machine tool industry after decades of development, has formed a number of technology, strength of the enterprises. These enterprises not only occupy an importa...

READ MORE -

A CNC flat bed lathe is a type of computer-controlled machining tool that is widely used in metalworking and manufacturing industries. Unlike traditional manual lathes, CNC (Computer Numerical Contr...

READ MORE

How to buy CNC machine tools

-

01

Contact Us

All of your quotes will be answered within 2 hours by our professional sales support.

-

02

Get A Free Quote

Use reliable parts and components to ensure product quality.

-

03

Fast Delivery

You can expect your order fulfilled within 60 days after placing the order.

-

04

After-sale Support

You can enjoy a one-year many for all of our produons.

Products

Message